- +86 15036470528

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

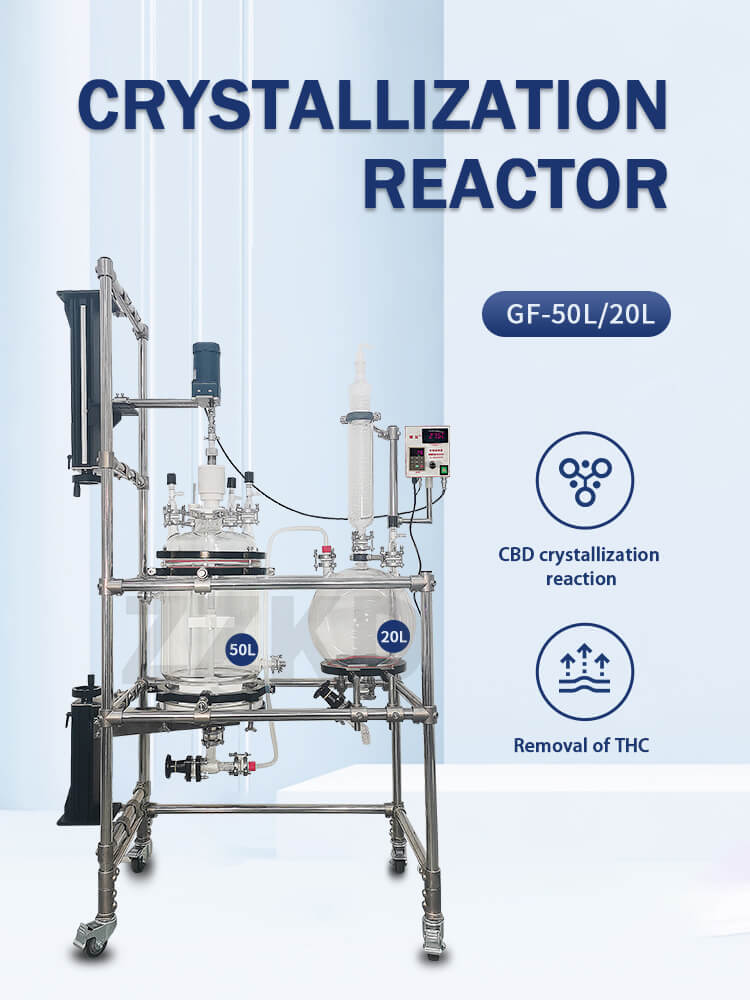

A crystallization reactor is a vessel designed to facilitate the crystallization of a substance from a solution or melt. Reactors typically contain a solution or melt of the substance to be crystallized, as well as solvents and other components that may be required for the crystallization process, such as nucleating agents or stabilizers.

Crystallization reactors are used in a variety of industries including pharmaceuticals, chemicals, food and materials science. The purpose of crystallization is to produce crystals of the desired size, shape and purity, which can then be further collected and processed as required.

1. High Purity: Crystallization reactors can produce crystals of very high purity, making them ideal for applications that require high purity, such as pharmaceuticals, food, and electronics.

2. Precise control: The temperature, pressure and other parameters of the crystallization process can be precisely controlled in the reactor, so as to better control the size, shape and other properties of the crystal.

3. Scalability: The crystallization reactor can be easily scaled up or down to accommodate different production volumes, making it suitable for both small-scale laboratory work and large-scale industrial production.

4. Energy Efficiency: By optimizing the crystallization process in the reactor, energy consumption can be reduced and the overall efficiency can be improved, resulting in cost savings and environmental benefits.

5. Reduced labor requirements: Crystallization reactors can be automated to a large extent, reducing manual intervention and labor costs.

6. Reproducibility: By using a crystallization reactor, consistent results can be obtained, which is very important for quality control and process validation.

The advantages of crystallization reactors make them a popular choice for producing high-quality crystals in various industries.

1. Drugs: Crystallization is a critical step in drug production because it can help purify and isolate active ingredients and control their release and bioavailability. Crystallization reactors are used in the production of a variety of pharmaceutical products, including drugs, vitamins and supplements.

2. Chemicals: Crystallization reactors are used to produce a wide range of chemicals including fertilizers, polymers and specialty chemicals. Crystallization can be used to purify and separate different components, as well as to control the properties of the final product.

3. Food and Beverage: The food and beverage industry uses crystallization to produce a variety of products including sugar, salt, chocolate and honey. Crystallization can be used to control the texture, appearance and flavor of these products.

4. Materials Science: Crystallization reactors are used in materials science to produce high-quality crystals for a variety of applications, including electronics, optics, and energy storage.

5. Mining: The mining industry uses crystallization to extract and purify minerals from ores. Crystallization can be used to separate different minerals and control their properties, making it an important part of mineral processing.

The versatility and effectiveness of crystallization reactors make them an invaluable tool in many different industries.

The operation of a crystallization reactor may vary depending on the specific design and application of the reactor, but the following are some general steps involved in the operation of a crystallization reactor:

1. Preparation: The reactor is cleaned and ready for use, adding necessary components such as solvent and nucleating agent.

2. Heating: Heating a solution or melt to a specific temperature to dissolve the solute.

3. Cooling: The solution or melt is slowly cooled to a specific temperature to promote the formation of crystals. The cooling rate and temperature profile can be carefully controlled to obtain the desired crystal size, shape and purity.

4. Nucleation: Nucleating agents can be added to the solution or melt to facilitate the formation of crystals. Nucleating agents can be added at specific times during cooling to control the size and number of crystals formed.

5. Separation: The crystals are separated from the remaining solution or melt using a filtration or centrifugation process.

6. Drying: The crystals are dried to remove any residual solvent or moisture.

7. Quality Control: The final product is analyzed to ensure it meets the required quality specifications.

In addition to these steps, the operation of a crystallization reactor may involve the use of various sensors and monitoring systems to track the progress of the process and make adjustments as needed. Reactors can also be designed to allow the addition of other components, such as stabilizers or modifiers, to control the properties of the final product.

A crystallization reactor typically involves heating the solution or melt to dissolve the solute, cooling the solution or melt to promote crystal formation, adding a nucleating agent to promote crystal growth, separating the crystals from the remaining solution or melt, and drying the crystals to remove any remaining solvent or moisture.

Crystallization reactors are used in a variety of industries including pharmaceutical, chemical, food and beverage, materials science and mining.

The crystallization process can be affected by factors such as temperature, cooling rate, nucleating agent, stirring rate, solvent composition, and impurities in the solution or melt.

MODEL | GF-10L/5 | GF-20L/10L |

Material capacity | 10L | 20L |

Jacket capacity | ≈2L | ≈5L |

Receiving flask | 5L | 10L |

Flange diameter | 265mm | 265mm |

Reactor body and cover | Flanged joint, the vacuum degree of machine is -0.098MPA | |

Variable-frequency governor | Digital temperature and rotate speed | |

Rotate speed | 0-400r/min | |

Seal | Self-lubricating mechanical seal | |

Filter base plate | PTFE filter sand core | |

Bore diameter of sand core | 0.1-200μm (Optional) | |

Motor power | 120W/1:3 | |

Power of explosion-proof motor | 180W | |

Voltage | 220V/50Hz which can be customized according to customer requirements | |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap